hardness test is used to estimate|hardness tester for thin material : bulk Hardness testing is crucial for assessing the strength, durability, and wear resistance of materials. It helps determine the suitability of a material for specific applications, ensuring quality control and reliability in critical components . Resultado da Vanguard Restrictions; Addressing Virtualization-based security (VBS) settings on Windows 10 | VAN9005 | VALORANT; Addressing cheating in .

{plog:ftitle_list}

189 linhas · 30 de out. de 2018 · 0042: Eslovénia: 386 +386: 00386: Eustónia: 372 +372: 00372: Etiópia: 251 +251: 00251: E.U.A. 1 +1: 001: Federação Russa: 7 +7: 007: Féroé: 298 +298: 00298: Filipinas: 63 .

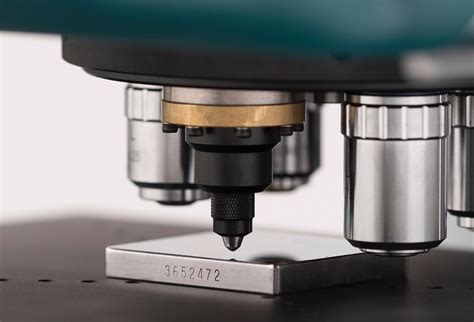

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .Hardness testing is crucial for assessing the strength, durability, and wear resistance of materials. It helps determine the suitability of a material for specific applications, ensuring quality control and reliability in critical components .For example, hardness from indentation tests on steel and copper alloys can be used as a rough guide to estimate tensile strength. Hardness tests, in most cases, are rapid and repeatable, and in many instances nondestructive. Therefore, hardness test .

This test is an alternative to Brinell hardness, and it is relatively easier to use because it does not depend on the cone diameter or size of the indenter. The article also briefly covers how to perform the Vickers hardness test. Read on .

While all indentation hardness tests generally serve the same purpose, each one has definite advantages that make the test more applicable to certain types of materials and part geometries. Brinell is used primarily on forgings and cast iron. The rebound test is used on large rolls. Vickers and Knoop tests are used on very small or thin parts andThe three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All three methods involve indentation of the material. The hardness is calculated by measuring the force applied and comparing this to some geometrical aspect of the indentation such as the surface area or depth.These tools can be used to perform a quick scratch test on a mineral sample to estimate its hardness. Mohs Hardness Testing Tips. To ensure accurate results and preserve the integrity of the minerals being tested, it is important to follow these tips: . Engineers use hardness tests to select appropriate materials for specific applications .

Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a material with a very small impression have been developed to attempt to estimate these properties. Explaining the scales and techniques used by each to calculate the hardness of materials and their suitability for different materials. What are Hardness Testers? . Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms .

Microhardness tests apply considerably lighter loads compared to other methods. Precisely cut diamonds are used for these tests, which most often measure hardness in small, localized regions of parts. Microhardness tests are best used to determine case depths of case hardened parts. Two types of diamonds are used in microhardness tests.

Brinell Hardness Test Equations, Calculators and Review . The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is measured and a Brinell hardness number is calculated from this diameter. Vickers hardness test. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. The Leeb hardness test can be used as a non-destructive method where a regular-shaped rock sample is difficult to obtain (in rocks and/or historical structures) and to estimate the rock properties .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is .

why is hardness testing important

Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid. The common test methods include: – Brinell. Vickers. Rockwell. The hardness figures do not have units.

Certaincommercialentities,equipment,ormaterialsmaybeidentifiedin thisdocumentinordertodescribeanexperimentalprocedureorconcept adequately . 📖 How to Test for Water Hardness at Home. There are a number of ways to test for water hardness at home, including using an at-home test kit, testing your water with a laboratory, . The easiest way to calculate water .Another tool used to make these tests is the pocket hardness tester. This tool consists of a scale arm with graduated markings attached to a four-wheeled carriage. A scratch tool with a sharp rim is mounted at a predetermined angle to the testing surface. In order to use it a weight of known mass is added to the scale arm at one of the .

After the test, the preliminary test force is removed and the indenter is removed from the test specimen. Types of Rockwell Scale Table-1 below gives the information on the type of indenter, the magnitude of the major load, and common applications for each of the hardness scales as per ASTM standard E18 (1984).

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5) A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a .Welcome back to the Ask the Expert blog. The blog is designed to help educate you on all things retaining rings and wave springs. This week, we talk about tensile strength and why it’s important in wave spring and retaining ring design. To ensure you know how a material will perform in a working environment, several physical properties can be measured to better understand .Use the appropriate formula for the Rockwell scale being used to calculate the Rockwell hardness number (RHN): For the Rockwell A scale: RHN = 100 – (d / 0.002mm) . load, and longer duration of load application, and report the Brinell hardness number (BHN) of the material. Rockwell hardness tests use a diamond cone or steel ball indenter .

The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can be varied. With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te. They can be used to scratch test minerals and estimate their relative hardness in the field, contributing to accurate identification and classification of rocks and minerals. Mohs Scale in Gemology Mohs Hardness Scale is a practical method for measuring the hardness and scratch resistance of minerals and gemstones.

The hardness testing results are expressed using different scales that express the Rockwell hardness value based on the major load used during the test. The B (100 kilogram-force) and C (150 kilogram-force) scales are the most common.properties of materials, hardness tests can be used to estimate the tensile strength of some metals without the need to perform more destructive mechanical testing. 2 S . The Rockwell hardness test is based on the difference of indenter depth from two load applications. An indenter is pressed into the material under an initial minor load to .

types of hardness testing methods

webVea el resumen de Alianza Petrolera vs Deportes Tolima, en la fecha 17 de Liga Betplay I-2022. | Liga Betplay | futbolred.com.

hardness test is used to estimate|hardness tester for thin material